Porous materials and coatings are widely used in chemical machine building and in other sectors where effective surface is required, as well in production of catalysts, etc.

Porous materials are generated from metals and alloys by way of electron-beam evaporation of several substances and subsequent condensation of the mixed vapour flow on a heated substrate. The temperature of the substrate and the rate of condensation, as well as the subsequent chemical or thermal treatment of the materials are the main process factors enabling adjustment of the pore size, shape and volume.

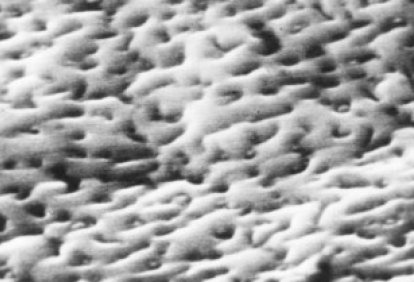

Porous materials based on pure metals and alloys are made as sheets up to 2 mm thick. Their porosity may be up to 40%, pores being of a round shape and sized from 0.3 to 6 µm.

At the customer’s request, ELTECHMASH can apply microporous coating of metallic or ceramic-metallic type on a solid smooth surface, on a porous substrate of on a grid substrate.

|

| Porous condensed material texture |

Coated surface sizing:

- flat rectangular surface – up to 600x600 mm;

- flat disk-shaped surface (diameter) – up to 800 mm;

- cylindrical surface (diameter) – up to 220 mm, length – up to 400 mm.

The porous material production technique has been patented: Ukrainian Patent No. 46855 dd. 17.06.2002.