The outstanding feature of the universal industrial electron-beam Installation lies in the fact that it can be used for:

1. Melting metals and alloys and producing shaped ingots of the diameter from 70 to 300 mm and up to 2000 mm long or blocks sized from 70x70 to 300x300 mm and up to 2000 mm long;

2. Application of coating on turbine blades of the maximum size: diameter 300 mm, length 550 mm;

3. Production of composite vapour-condensed materials of the dispersion-strengthened, microlayered and microporous types in the form of sheet rolls with the diameter up to 750 mmand thickness up to 5 mm.

Our company has designed two types of industrial electron-beam plants based on electron-beam heaters with hot ribbon-type cathode and gas-discharge heaters with cold cathode.

|

|

|

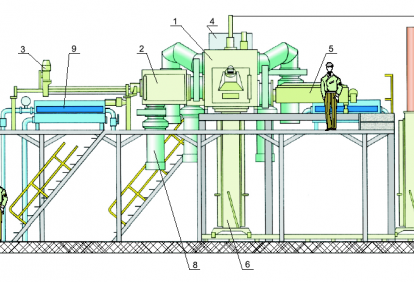

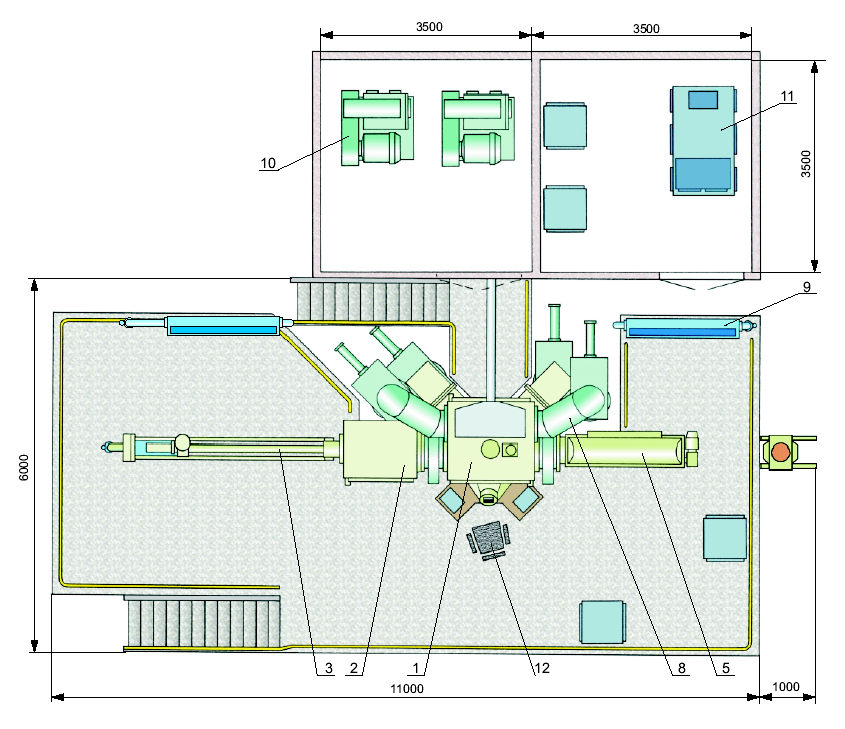

1. Process chamber 2. Loading chamber 3. Horizontal feeder mechanism for workpieces to be coated 4. Vertical suspension mechanism for workpieces to be coated 5. Meltable ingot feeder mechanism 6. Ingot feeding mechanism |

7. Ingot 8. Vacuum system 9. Cooling system 10. Fore-vacuum pumps 11. Plant power supply system 12. Operator’s place |

Technical parameters of the Installation

| Parameter Description | Value |

| Installed power, kW | 300 |

| Electron-beam gun (EB gun) accelerating voltage, kV | 20 |

|

Quantity and rated power of EB guns, n x kW |

4x60 |

| Maximum size of meltable billets, mm: - cross-section - length |

200x200 |

|

Size of output ingots, mm: - length |

70 - 300x300 |

| Quantity of simultaneously used melting crystallizers | 1 |

| Size of evaporable ingots, mm - diameter - length |

70 |

| Maximum size of condensation surface, mm

- flat rectangular surface - length |

550x360

300 |

| Load capacity of horizontal feeder mechanism for workpiece to be coated, kg | 50 |

| Load capacity of suspension mechanism for workpiece to be coated, kg | 100 |

| Floor space required, m2 | 140 |

| Operating vacuum level inside process chamber, Pa | 6x10-3 - 1x10-2 |