ELTECHMACH has designed the industrial electron-beam equipment for obtaining materials and coatings by high-speed evaporation and subsequent condensation of metal and non-metal materials on a substrate in the vacuum environment. The equipment allows to use a number of process techniques (vapour flow management by way of separation and alternation, substrate rotation and temperature monitoring and management, etc.) in the automatic or semi-automatic mode.

The output composite, porous, dispersion-strengthened, microlayered and gradient-type materials may be in the form of rolls of sheet material with the diameter up to 1000 mm and thickness up to 5 mm.

The technology of production of the said materials is protected by Ukrainian Patent No. 74155 dd. 15 November 2005.

Technical parameters of the Installation

| Parameter Description | Value |

| Installed power, kW | 280 |

| Three-phase 50-Hz industrial frequency mains voltage, V | 380 |

| Electron-beam gun (EB gun) accelerating voltage, kV | 20 |

| Quantity and rated power of EB guns, n x kW |

8x60 |

| Max. diameter of substrate to be coated, mm | 1000 |

| Condensate thickness, mm | 0,1-5 |

| Rate of condensation, µm/min: - for metal - for ceramics |

up to 50 |

| Number of crucibles *, pcs. - 100-mm diameter - 70-mm diameter |

2 |

| Length of evaporated ingots, mm | 500 |

| Ingot feed rate, mm/min | 0,28-280 |

| Load capacity of workpiece suspension and rotation mechanism, kg | 100 |

| Weight (tentative) of plant, ton | 20 |

| Floor space required, m2 | 80 |

| Operating vacuum level inside process chamber, Pa | 6x10-3 - 1x10-2 |

*The crucibles are interchangeable and may be arranged in any sequence

|

|

|

|

|

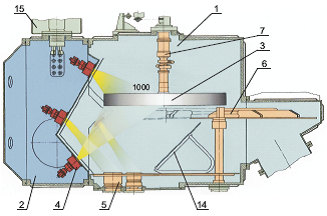

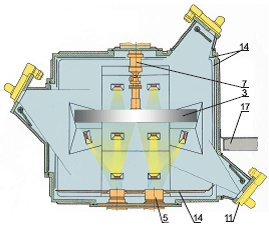

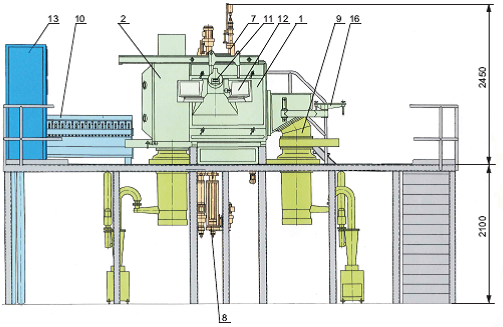

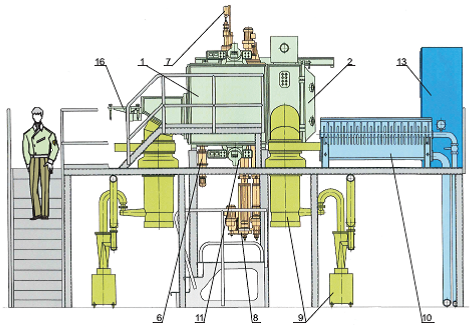

1. Process chamber 2. Gun chamber 3. Workpieces 4. Electronic guns 5. Crucible unit 6. Damper 7. Workpiece suspension and rotation mechanism 8. Ingot feeder mechanism |

9. Vacuum system 10. Cooling system 11. Viewing system 12. Control panel 13. Control cabinets 14. Screens 15. High-voltage lead-in 16. Handling manipulator |