ELTECHMACH has developed an industrial electron-beam Installation for refining and melting of material into ingots and blocks. This industrial equipment allows to melt feedstock either directly into the crystallizer or via an intermediate vessel. The feedstock may be in the form of ingots, lumps, rods, and any kind of waste, e.g. compressed chips (shavings).

The equipment yields high-quality ingots and blocks, according to the chemical and phase composition requirements, of high-reactive and refractory metals, such as tungsten, titanium, molybdenum, niobium, hafnium, zirconium, nickel, copper, cobalt and iron; heat-resistant and heatproof alloys, as well as intermetallides such as Ti3AI, TiAl, Ni3AI, NiAI, etc.

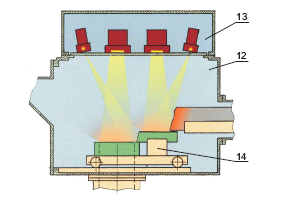

The Installation equipped a glow discharge guns with cold cathode.

Technical parameters of the Installation

| Parameter Description | Value |

| Installed power, kW | 460 |

| Three-phase 50 Hz industrial frequency mains voltage, V | 380 |

| Electron-beam gun (EB gun) accelerating voltage, kV | 30 |

|

Quantity and rated power of EB guns, n x kW |

4x100 |

| Maximum size of billet to be melted, mm: - cross-section - length |

200x200 |

| Maximum size of output ingots, mm: - cross-section - length |

200x300 |

| Ingot feeding rate, mm/min | 8,5-850 |

| Dimensions of the molds, included to the Installation, mm |

ø70, ø100, ø130 200×300 |

| Dimensions of the intermediate tank, mm |

300×300 |

| Vacuum level inside process chamber, Pa | 1x10-2 - 1x10-3 |

| Floor space required, m2 | 65 |

| Weight of plant, ton | 20 |

|

|

|

|

|

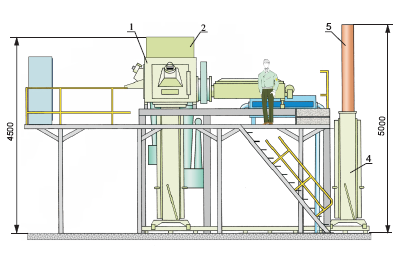

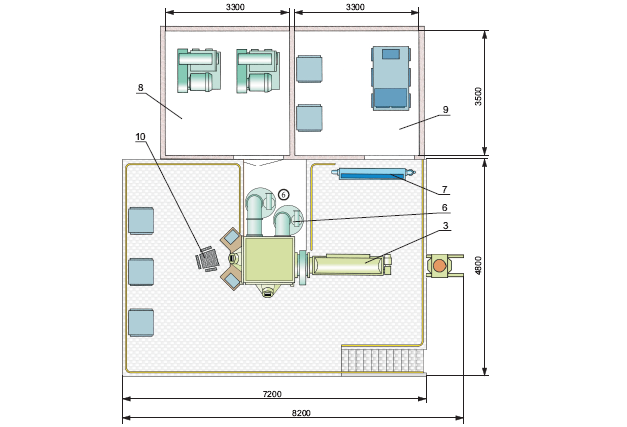

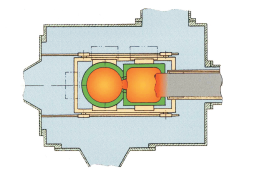

1. Process chamber 2. Electronic gun unit 3. Meltable workpiece feeding mechanism 4. Ingot feeding mechanism 5. Ingot |

6. Vacuum system 7. Cooling system 8. Fore-vacuum pumps 9. Plant power supply system 10. Operator’s place |