A modern extended-life thermal-barrier coating (TBCs) is commonly applied on any articles to be protected in a double-step process. In particular, such approach has been taken by Pratt and Whitney, USA. Under such approach, the inner metallic layer Ni(Co)CrAIYHfSi is applied by plasma spraying, whereas the outer ceramic layer by electron-beam deposition.

Moreover, such technical solution has been a common practice due to the fact that, until recently, it was not possible to add, using the EB technology, the required quantity of yttrium, hafnium, silicon and zirconium by way of evaporation from a single source.

A technological breakthrough in solving the problem was offered by ELTECHMACH. Our company has designed a new type of crucibles, which allow to remove the above restraints and to admix almost any quantity of alloying agents to heat-resistant alloys of MeCrAlY type, including Hf, Si, Y, etc. This invention opens up new opportunities of the electron-beam technology application in pursuit of perfection of the heat-barrier coating process:

- it is clear that application of the electron-beam technology is more cost-efficient because deposition of a composite double-layer coating of the MeCrAIYHfSi/Zr02-Y203 type is carried out on a single unit of equipment and within a single work cycle;

- there are no restraints, in terms of process, as to generation of double-layer TBC coatings, where the inner metallic layer is strengthened by disperse particles of oxide, carbide or boride compounds, which is very hard to achieve with the use of the plasma technology;

- there are no restraints, in terms of process, as to generation of double-layer TBC coatings with the gradient of the component concentration in the inner metallic layer, which is very hard to achieve with the use of the plasma technology, too;

- it is easy to generate thermal-barrier coatings consisting of separate interlaced microlayers such as metal/ metal, metal /cermet, metal/oxide, oxide / oxide, oxide/carbide, oxide /boride, with the layer thickness varying from 0.001 to 10-30 µm;

- the existing equipment makes it possible to start developing new types of ceramic materials for TBC coatings with enhanced fracture elasticity, which contain the so-called "self-control elements", viz. particles or microlayers able to “cure” any microfissures in ceramic material arising out of the “heating-and-cooling” thermal cycles.;

- an important field of further research is the development of a new EB technique for depositing new metallic materials used for heat resistant coating, in particular chromium-based materials.

The above tasks may be updated and/or further elaborated in case of any joint research or practical application projects.

The output capacity of the industrial electron-beam equipment is 20 to 50 thou. blades per year, depending on the type and size of blades.

The design of the plant is protected by Ukrainian Patent No. 40664 dd. 15 August 2001.

Coating ensures 3- to 5-fold service life extension of blades.

Technical characteristics of the Installation

|

Dimensions of the cylindrical cassette, mm, not more: - diameter - length |

250 500 |

|

Rotation speed of the horizontal shaft, rpm |

1-30 |

|

Number of crucibles, pcs. |

4 |

|

Inner diameter of crucibles, mm |

70 |

|

Length of evaporated ingot, mm, not more |

500 |

|

Feed speed of ingots, rpm |

0,5 – 350 |

|

Distance from the upper edge of the crucible to the rotation axis of the cassette or coating plane, mm |

350 |

|

Quantity and nominal power of electron guns: - for evaporation from the crucibles - for heating workpieces Type of electron guns – with direct heat tape cathode |

4х60 2х60 |

|

Installed power, kW - high voltage power sources - auxiliary equipment |

250 40 |

|

Rated operating accelerating voltage, kV |

20 |

|

Working pressure in chamber, Pa (Torr) |

6х10-3 – 6х10-2 (5х10-5 – 5х10-4) |

|

Rated three-phase AC voltage frequency of 50Hz, V |

380±10% |

|

Cooling water pressure, Pa (bar) |

3х105 – 4х105 (3 – 4) |

|

Productivity (when loading 12 blades), pcs./year |

~60 000 |

|

Overall dimensions, mm: - length - width - height |

11 500 8 500 4 000 |

|

Weight, kg, not more |

25 000 |

|

|

|

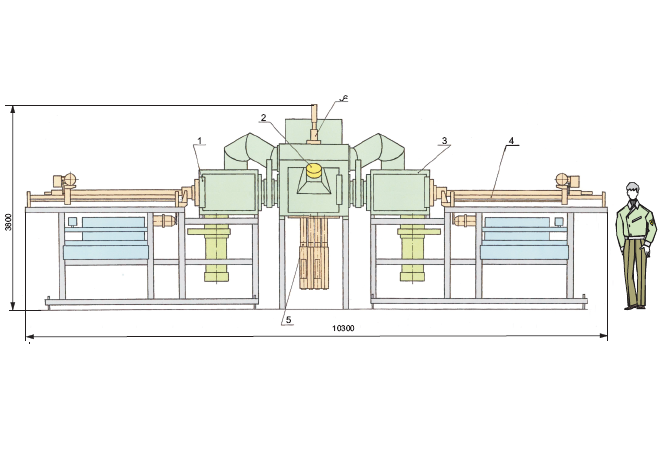

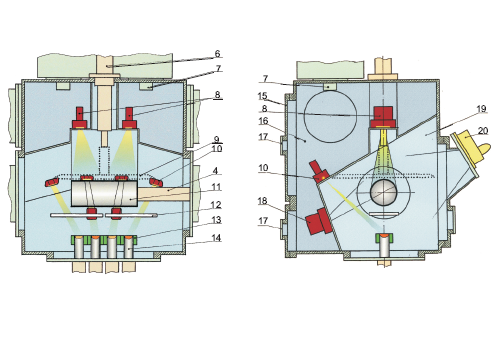

1. Left-side airlock feed chamber 2. Process chamber 3. Right-side airlock feed chamber 4. Workpiece horizontal feeder mechanism 5. Ingot feeder mechanism for evaporation 7. High-voltage lead-in 8. EB guns for workpiece downward heating 9. Disk-shaped workpiece 10. EB guns for ingot evaporation |

11. Cylinder-shaped workpiece cassette holder 13. Crucibles 14. Evaporated material ingots 15. Gun chamber cover 16. Gun chamber 17. Viewing port 18. EB guns for workpiece upward heating 19. Evaporation chamber 20. Viewing system |

|

| Overall view of the EB Unit L-1 |