This plant is intended for melting the feedstock in the form of powder, pellets, lumps, cylinder-shaped billets and compact billets into solid ingots or rectangular-shaped plates.

The plant is designed in two options: one uses electron-beam guns with filament type cathode and the other uses 100 kW gas-discharge guns with cold cathode.

Technical parameters of the Installation

| Parameter Description | Parameter Value |

| Size of output ingots, mm - diameter - length |

50, 60, 80, 100 |

| Size of intermediate vessel, mm | 110х110х50 |

| Size of output tablet, mm | diameter 100x10 100х80х10 |

| Size of compact billets, mm - diameter - length |

30-100 |

| Size of meltable pellets, mm | 5-20 |

| Volume of pellet hopper, litre | 10 |

| Compact billet feeding method | Horizontal and vertical |

| Size of melting chamber, mm - length - width - height |

1500 |

| Flat-beam electronic gun with ribbon-type cathode - quantity, pcs. - power per gun, kW - accelerating voltage, kV |

4 |

| Vacuum inside melting chamber | 1х10-3-1х10-4 |

| Power of high-voltage source, kW | 250 |

| Power of auxiliary equipment, kW | 30 |

|

|

|

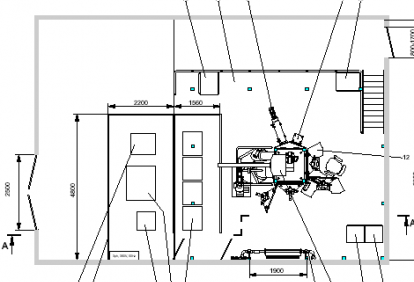

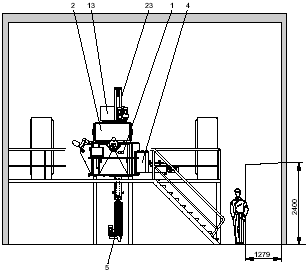

1. Process chamber 2. EB gun chamber 3. Compact billet feeder mechanism 4. Pellets feeder mechanism 5. Ingot drawing system 6. Oil-vapour pump DIP 3000 7. Oil-vapour pump DIP 8000 8. Fore-vacuum pump 9. Gate valve DN 250 10. Gate valve DN 400 11. Cooling system 12. Control panel |

13. Busbar bridge 14. Maintenance platform 15. High-voltage rectifier 16. Filament unit 17. High-voltage transformer 18. Start-up safety cabinet 19. Control cabinet 20. Reactor 21. Vacuum equipment cabinet 22. EB gun cabinet 23. Billet vertical feeder mechanism 24. Protective grid |