Among non-traditional energy sources, there are such environment-friendly and safe priorities are the energy derived form biomass, wind energy, geothermal energy and solar energy. In terms of relative cost-efficiency, the most promising option is the energy of direct solar radiation.

The prime policy in the field of solar power engineering consists in promotion of photovoltaic systems (PVSs), viz. the systems of direct conversion of the solar radiation luminous energy into electricity. As a basic material for creation of PVSs, high-purity polycrystalline or monocrystalline silicon is considered. For the time being, all PVS manufacturers are intent on using the comparatively cheap "solar-grade" silicon (C-Si), which is dirtier that semiconductor silicon.

ELTECHMACH has developed an industrial-scale technology for deriving C-Si from metallurgical-grade silicon, which includes multi-stage silicon purification with the use of various techniques and fluxes, depending on the extent of impurity and the nature of impurities.

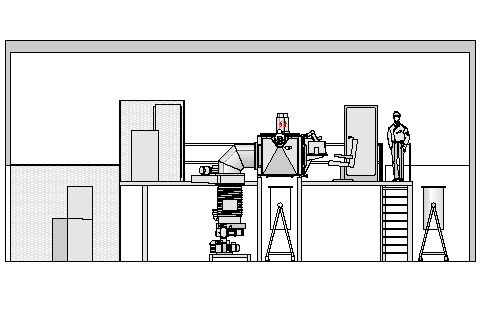

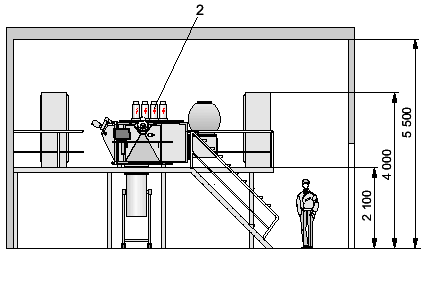

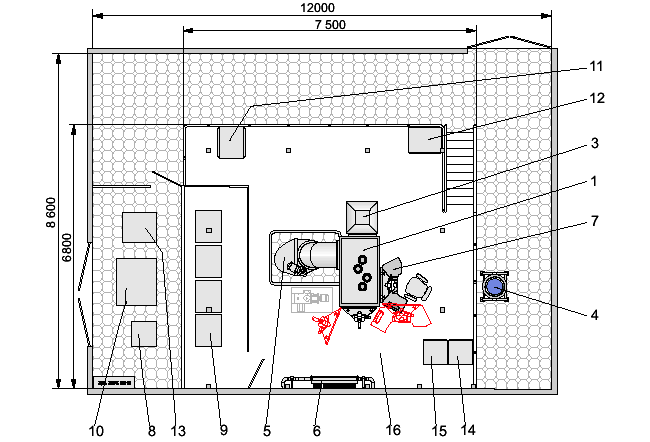

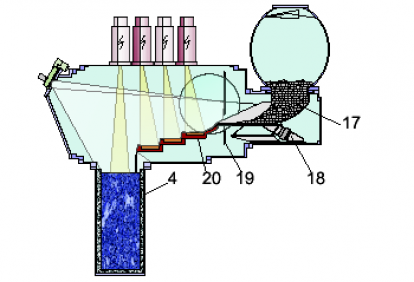

Our company has designed two types of industrial electron-beam Installations based on electron-beam heaters with hot ribbon-type cathode and gas-discharge heaters with cold cathode.

|

|

|

|

| 1. Process chamber 2. EB cold-cathode gun 3. Loading bunker 4. Receiving bunker 5. Vacuum system 6. Cooling system 7. Control panel 8. High-voltage rectifier 9. Filament unit 10. High-voltage transformer |

11. Start-up safety equipment cabinet 12. Programmable controller cabinet 13. Choke 14. Vacuum and drive control cabinet 15. Gun control cabinet 16. Maintenance platform 17. Feedstock 18. Electromagnetic vibrator 19. Screen 20. Cascade of intermediate trays (vessels) |